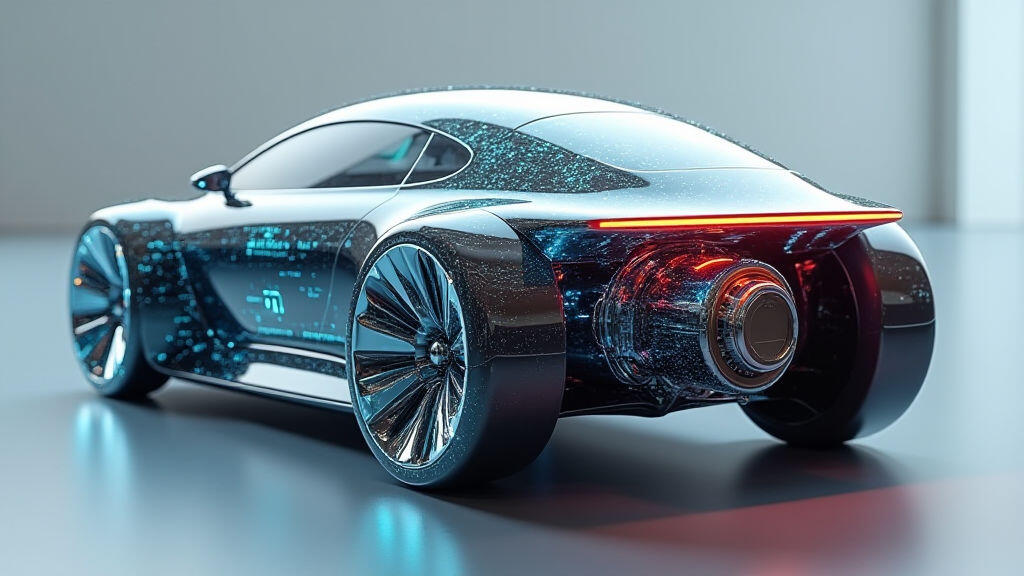

The automotive industry is undergoing a seismic shift. Driven by evolving consumer demands, stringent environmental regulations, and the accelerating adoption of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), manufacturers are relentlessly pursuing efficiency and performance gains across every component. Among these vital components, gear motors are experiencing a surge in attention. Automotive parts manufacturers are increasingly focusing on optimizing gear motor model performance, and for good reason. This article will delve into the key drivers behind this trend, the performance metrics being prioritized, the technologies enabling optimization, and the future outlook for gear motors in the automotive landscape, especially considering the current push for sustainability and autonomous driving.

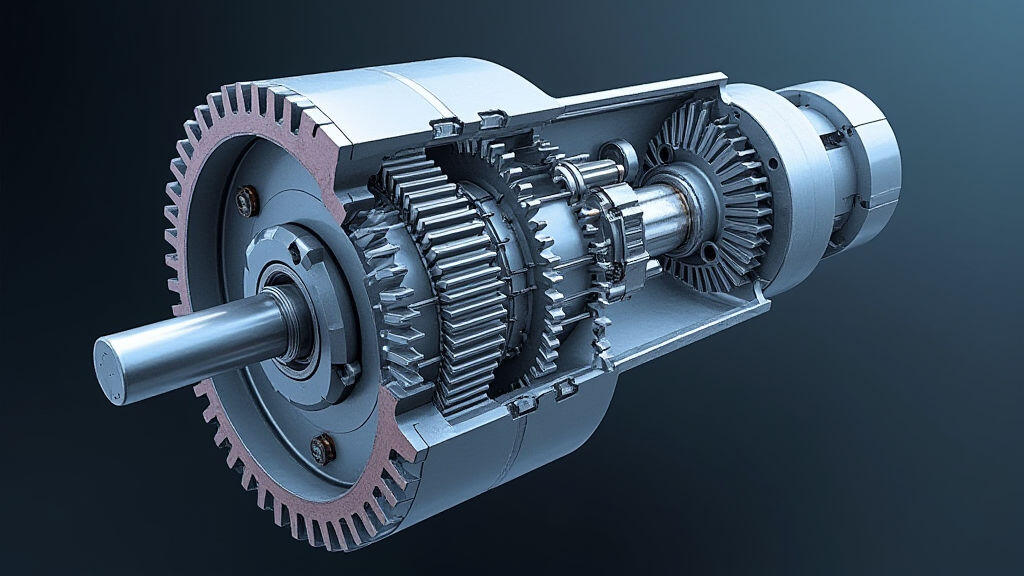

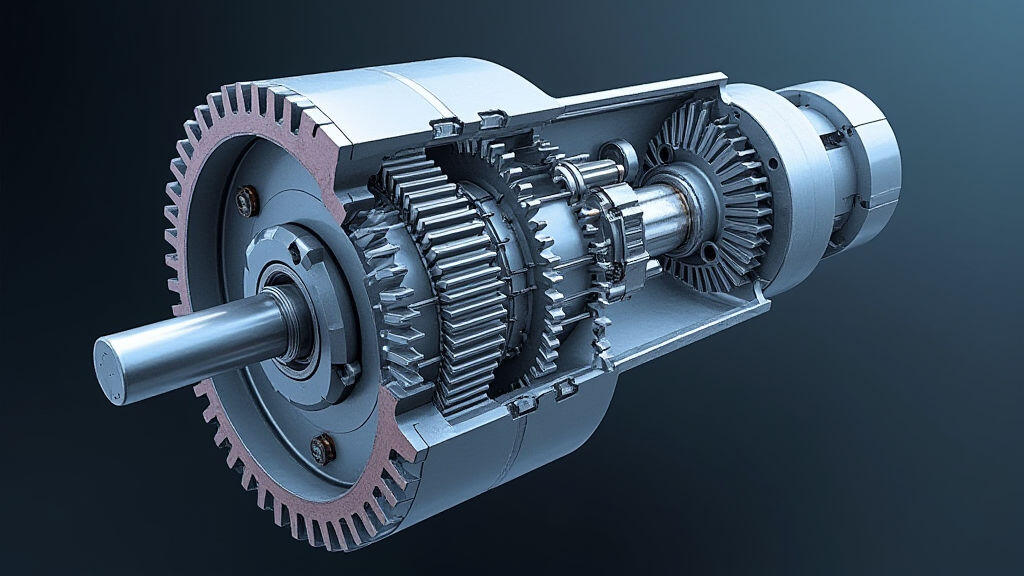

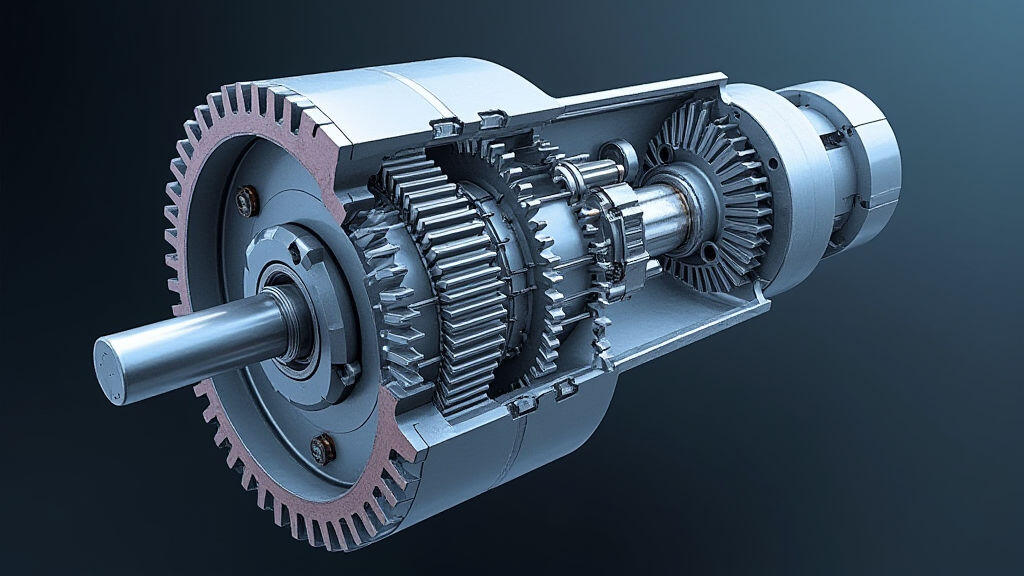

The core driver behind the focus on gear motor performance is the transformation of the automotive market. Traditionally, internal combustion engine (ICE) vehicles dominated. However, the electrification revolution, coupled with the increasing complexity of modern vehicles, has placed unprecedented demands on powertrain efficiency, power density, and reliability.

EVs, in particular, rely heavily on electric motors for propulsion, and gear motors play a crucial role in various ancillary systems, including power steering, power windows, seat adjustment, and braking systems. Here’s where optimized gear motor performance becomes paramount.

- Increased Power Density: EVs require smaller, lighter, and more powerful components to maximize range and minimize vehicle weight. Gear motors contribute to this goal significantly. Optimizing their design allows for higher torque outputs in smaller packages, vital for efficient vehicle operation.

- Enhanced Efficiency: Energy efficiency is crucial for extending EV range. Gear motors need to minimize energy losses during operation. Improvements in gear design, lubrication, and materials directly contribute to reduced energy consumption and improved overall vehicle efficiency.

- Improved Reliability & Durability: Modern vehicles are complex, and gear motors must withstand demanding operating conditions, including high temperatures, vibrations, and continuous use. Optimized designs enhance durability, reducing maintenance costs and improving vehicle reliability.

- ADAS Functionality: Advanced driver-assistance systems (ADAS) rely on a complex network of sensors and actuators. Gear motors are heavily utilized in these systems, driving mechanisms for features like adaptive cruise control, lane keeping assist, and automatic emergency braking. Precise and reliable gear motor operation is critical for the safe and effective functioning of ADAS.

Manufacturers are no longer satisfied with basic gear motor specifications. The focus has shifted towards optimizing specific performance metrics that directly impact vehicle performance and efficiency:

- Efficiency: This is arguably the most critical metric. Manufacturers are striving for gear motors with minimal energy losses, often measured as the ratio of output power to input power. Innovative gear geometries, reduced friction materials, and improved lubrication systems are key to achieving higher efficiency. Data suggests that even a 1% increase in gear motor efficiency can translate to a noticeable improvement in EV range.

- Torque Density: This refers to the amount of torque a gear motor can produce per unit volume or weight. Higher torque density allows for smaller, lighter gear motors capable of delivering the necessary power. Advances in materials science and manufacturing processes are pushing torque density boundaries.

- Backlash: Backlash refers to the play or looseness in the gear mesh. Excessive backlash can lead to inaccurate positioning and reduced system responsiveness, especially in applications like ADAS. Minimizing backlash is crucial for precision-driven systems.

- Noise, Vibration, and Harshness (NVH): A quiet and smooth-operating vehicle is a key differentiator. Gear motors contribute to NVH, especially at higher speeds. Optimizing gear design, using noise-dampening materials, and employing advanced manufacturing techniques can significantly reduce noise and vibration levels.

- Reliability and Lifespan: The dependability of a gear motor is paramount. Factors like bearing quality, lubrication, and overall design contribute to the motor's longevity. Extended warranties and reduced maintenance requirements are increasingly important considerations.

Technologies Driving Optimization

Several technological advancements are enabling manufacturers to achieve superior gear motor performance:

- Advanced Materials: The use of lightweight materials like aluminum alloys, magnesium alloys, and composite materials reduces overall motor weight while maintaining strength and durability. Sophisticated coatings reduce friction and wear.

- Precision Manufacturing: Advanced manufacturing techniques, including CNC machining, laser cutting, and 3D printing, enable the production of highly precise gear designs with minimized backlash and improved accuracy.

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD): These simulation tools allow engineers to model gear motor performance under various operating conditions, identify potential weaknesses, and optimize the design for maximum efficiency and reliability before physical prototyping.

- Smart Sensors and Monitoring Systems: Integrating sensors into gear motors allows for real-time monitoring of parameters like temperature, vibration, and torque. This data can be used to optimize performance, detect potential failures early, and enable predictive maintenance. MES-Drive, for example, utilizes a suite of sensors to dynamically adjust motor parameters based on real-time operating conditions.

- Advanced Lubrication Systems: Optimized lubrication minimizes friction, reduces wear, and extends gear motor lifespan. Advanced lubrication systems often incorporate self-healing lubricants and intelligent lubrication monitoring.

The Future of Gear Motors in Automotive

The future of gear motors in the automotive industry is inextricably linked to the ongoing trends of electrification, autonomous driving, and increased vehicle complexity.

- Further Integration with Electric Powertrains: As EVs become more prevalent, gear motors will play an even greater role in power management, energy recovery, and vehicle control. Expect to see more sophisticated gear motor designs integrated directly into electric motor units.

- Rise of Intelligent Gear Motors: The integration of sensors, data analytics, and machine learning will lead to the development of “intelligent” gear motors capable of self-optimization, predictive maintenance, and adaptive performance. MES-Drive is actively exploring AI-powered control algorithms to dynamically adjust gear ratios and lubrication parameters for optimal efficiency and reliability.

- Focus on Sustainability: Manufacturers are increasingly prioritizing sustainable gear motor designs, using eco-friendly materials, reducing energy consumption, and minimizing waste in the manufacturing process.

- Miniaturization and Scalability: There's a continuous drive to miniaturize gear motors while maintaining performance. This will enable their use in a wider range of automotive applications, including micro-mobility solutions and advanced vehicle features.

Conclusion

The automotive industry’s accelerating transition towards electrification, autonomous driving, and increasingly sophisticated vehicle features is driving a significant focus on gear motor model performance optimization. Manufacturers are prioritizing efficiency, torque density, reliability, and NVH characteristics, leveraging advanced materials, precision manufacturing, and intelligent control systems. The future of gear motors lies in deeper integration with electric powertrains, the rise of intelligent and sustainable designs, and continued miniaturization. As the automotive sector continues to evolve, optimized gear motor performance will be critical for unlocking the full potential of EVs, enabling the development of safer and more efficient autonomous vehicles, and ultimately, shaping the future of transportation. The ongoing advancements in gear motor technology, as exemplified by companies like MES-Drive, are not just incremental improvements; they represent a fundamental shift in how automotive components are designed and manufactured, with far-reaching implications for the entire industry and the future of mobility.

Leave A Reply

Your email address will not be published. Required fiels are marked